One of the basic and important features of concrete that always has to be accounted for is it’s expansion and contraction due to changes in temperature and moisture. Failure to add in expansion joints into every concrete project in the correct places and number will result in large cracks forming, sooner or later. In larger buildings it’s more important than ever to design in and implement the proper construction joints. Here I’ll provide more information on why they’re necessary and how to design them in from the start.

Knowing Where To Design In The Expansion Joints is A Science

Going back 200 years in construction with concrete, engineers have long known the importance of putting in plenty of expansion joints. When pouring larger structures, it becomes even more important since the failure could be catastrophic leading to entire bridges, buildings, and other projects crumbling to the ground in just a few short years. On the other hand, once the joints are designed in scientifically, concrete can last hundreds of years without a problem.

The question is, how do engineers and architects know where and how many joints are required for a given project? In the past, most of them relied on solid experience and education, both before they begin their careers and as they learned on the job.

Now, however, there are computer programs to assist in the design of concrete projects that will add in the joints where needed. In addition to that, there are guides such as “Design and Construction Of Joints In Concrete Structures,” published in 1996, that provide extensive advice to structural engineers and design engineers on the placement and frequency of expansion joints in concrete.

Visit: http://mnconcretecouncil.org/how-to-find-council-concrete-paving-slabs-for-less/ for more information.

It covers the various types of joints such as movement joints, expansion and contraction joints and others so that the civil engineer or concrete materials engineer will know exactly how to build a structure and not have it crack in a few years down the road.

Some Joints Are Known And Predetermined

In most concrete pours there are basic rules established that there will be a joint every so many feet throughout the project. Things like driveways, roads, patios, and walls have been built for ages and the joint layout is mostly predetermined.

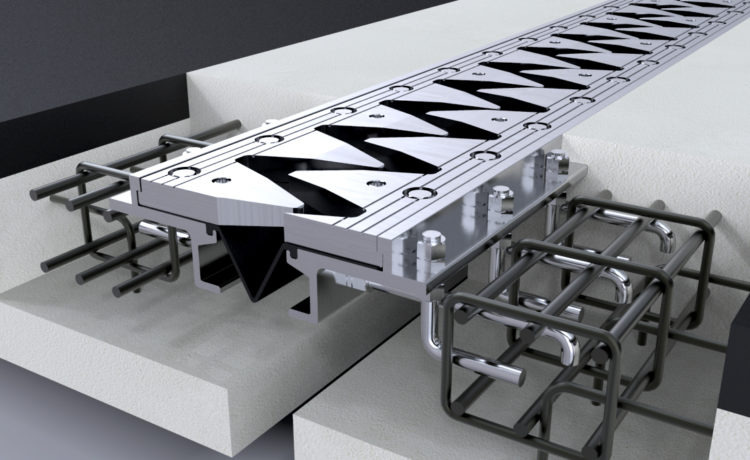

Construction joints are installed to allow the building to move horizontally at a right angle to the ground as ambient temperature rises and lowers without allowing movement vertically. There are set rules that most engineers follow and use in their designs repeatedly that account for this movements under stress. Most projects that are built today are made up of thousands of smaller concrete pours, each with their own joints. Click here for more information.

New Designs Need Careful Attention

When a standard building is constructed of concrete, it is normally made from standard parts that have been poured and tested for ages. However a new design using non-standard pours is where problems can arise. The design must be scrutinized carefully to make sure that all contingencies are considered and expansion is taken into consideration for both moisture and temperature variations.

Helpful books like “Design and Construction Of Joints In Concrete Structures” can streamline the learning curve and eliminate some of the guesswork involved in building unique structures and having them last through the ages.